Signs Your Engine Mounts or Suspension Bushings Need Replacement

Every vehicle or industrial machine relies on precision-engineered rubber components to absorb vibration, reduce noise, and ensure stability. Among these, engine mounts and suspension bushings play a crucial role. Over time, wear and tear in these components can affect not just comfort but also performance and safety.

If you’ve been noticing unusual vibrations, noise, or instability, it may be time to check for engine mounts replacement signs or suspension bushings replacement.

In this article, we’ll help you understand what to look for, why replacement matters, and how partnering with a quality rubber mounts and bushings supplier can ensure durability and peace of mind.

Why Engine Mounts and Bushings Matter

- Engine Mounts – The Unsung Stabilizers

Engine mounts act as the bridge between the engine and the chassis, supporting weight while isolating vibration. Their primary function is to prevent engine movement during acceleration, braking, or road shocks.

High-quality rubber-metal bonded mounts are designed to absorb dynamic forces and maintain precise alignment, improving both performance and NVH (Noise, Vibration, Harshness) characteristics.

- Suspension Bushings – The Link Between Comfort and Control

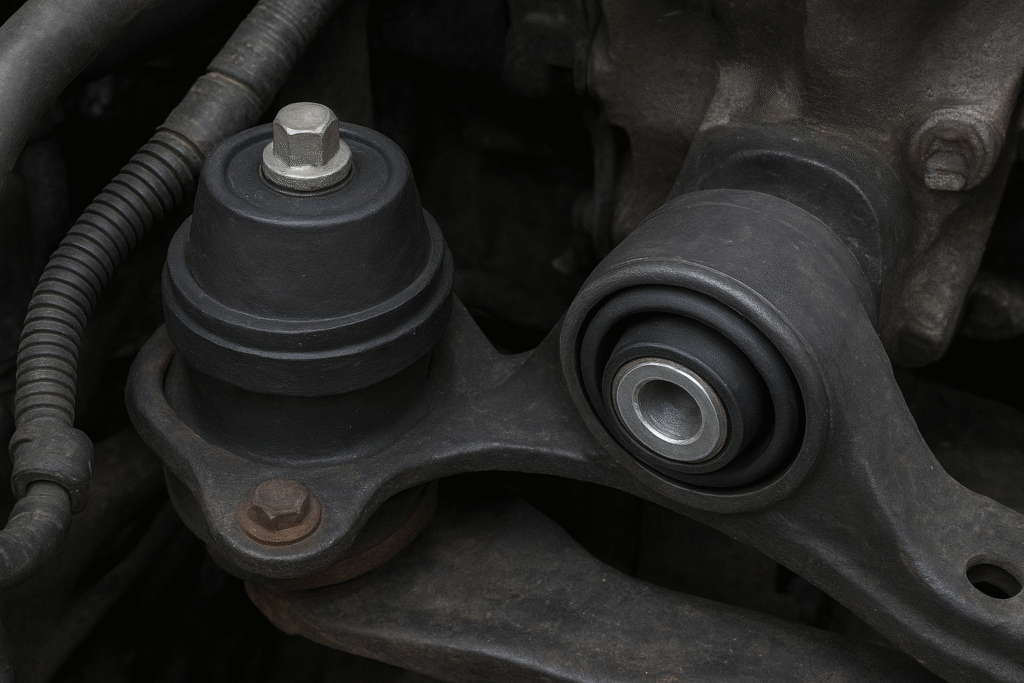

Suspension bushings sit between suspension arms, subframes, and the vehicle body. They allow controlled movement and cushion impact from uneven roads. When bushings degrade, ride comfort drops and handling becomes unpredictable.

According to the Automotive Component Manufacturers Association of India (ACMA), vibration isolation systems such as mounts and bushings are among the fastest-growing component categories in India’s ₹4.2 lakh-crore automotive ecosystem, driven by both OEM and aftermarket demand.

Top Signs Your Engine Mounts Need Replacement

- Excessive Vibration in the Cabin

If you feel stronger-than-usual vibrations through the steering wheel or seat, it’s often one of the first engine mounts replacement signs.

As rubber hardens or cracks, its damping ability drops, transmitting engine pulses into the body.

- Clunking or Thudding Sounds

A broken or loosened mount may allow the engine to shift during acceleration or gear changes, creating a dull thud. This not only feels unpleasant but can damage adjacent components like hoses or wiring harnesses.

- Misaligned Engine or Uneven Idling

Worn mounts cause the engine to tilt or misalign. You might notice uneven idling, poor throttle response, or excessive engine rocking when revving.

A quality rubber mounts and bushings supplier can provide reinforced designs that prevent such misalignment and extend service life.

- Visible Damage

Inspect mounts periodically for cracks, oil saturation, or detached metal inserts. Once the bond between rubber and metal fails, the mount loses structural integrity.

Top Signs Your Suspension Bushings Need Replacement

- Unstable Handling and Steering

If your car sways excessively, feels loose, or doesn’t hold corners as before, worn suspension bushings could be the cause.

Aging bushings alter suspension geometry, reducing stability at higher speeds.

- Uneven Tire Wear

Worn bushings affect wheel alignment, leading to uneven or rapid tire wear. This not only impacts safety but also increases running costs.

- Squeaking or Creaking Sounds

When the rubber layer inside a bushing hardens or tears, metal-to-metal contact can occur. You may hear squeaks or knocks while going over bumps or turning the steering wheel.

- Harsh Ride and Increased Vibration

Old bushings lose elasticity, causing every bump and vibration to be transmitted into the chassis.

According to a BCG industry report, improved ride comfort and NVH refinement are key differentiators in vehicle design—and bushings are central to achieving that refinement.

What Causes Mounts and Bushings to Fail

- Continuous Load Cycles: Millions of compression and shear cycles fatigue the material.

- Oil or Chemical Exposure: Engine oil and brake fluids can deteriorate rubber compounds.

- Extreme Temperatures: Heat accelerates oxidation, while cold causes hardening.

- Poor Material Quality: Low-grade rubber loses elasticity quickly, reducing service life.

- Improper Installation or Alignment: Incorrect torque or fitment causes premature failure.

A 2024 study by FICCI noted that poor-quality rubber components contribute to nearly 15–20% of unplanned vehicle maintenance in India’s commercial fleet segment—highlighting the need for trusted suppliers and durable materials.

When to Replace and How to Choose the Right Components

The ideal replacement interval varies by usage, but typically:

- Engine mounts: Every 5–7 years or 80,000–100,000 km

- Suspension bushings: Every 50,000–70,000 km or earlier for rough-road vehicles

When selecting replacements, always consider:

- Material composition (EPDM, NBR, or Natural Rubber blends)

- Load capacity and vibration frequency range

- Compatibility with your vehicle or machine type

- Certification and quality testing

McKinsey & Company highlights that future-ready automotive suppliers are investing heavily in compound R&D and fatigue testing to ensure consistent quality across extreme environments.

How Corrotek Ensures Long-Life Rubber Components

Based in Manesar, Gurgaon, Corrotek specializes in precision rubber-metal bonded components, including mounts, bushings, seals, and cushions for both automotive and industrial applications.

Our Advantages

- Material Innovation: Custom rubber compounding (NBR, EPDM, HNBR) for superior fatigue resistance.

- Rigorous Testing: Every batch undergoes compression, shear, ozone, and thermal aging tests.

- Precision Engineering: Tight tolerance bonding between rubber and metal ensures dimensional stability.

- ISO-Aligned Processes: Adherence to ISO 9001 and IATF 16949 standards for global OEMs.

- Customization: Tailored NVH solutions for passenger, commercial, and industrial systems.

EY India’s Manufacturing Outlook points out that Tier-2 and Tier-3 suppliers with material testing capabilities—like Corrotek—are driving the next phase of India’s component quality revolution.

India’s Growing Market for Quality Rubber Components

The Financial Express reports that India’s auto-component exports could reach USD 35 billion by 2028.

Clusters like Gurgaon-Manesar are leading this charge, combining engineering precision with cost competitiveness.

Organizations like ACMA and FICCI have emphasized the importance of vendor quality audits, testing infrastructure, and skill upgradation to meet global standards factors that Corrotek already integrates in its operations.

Why Partner with a Trusted Rubber Mounts and Bushings Supplier

Choosing the right rubber mounts and bushings supplier is more than a purchase decision it’s an assurance of safety, performance, and uptime. A trusted supplier ensures:

- Consistent material quality

- Reliable bonding and curing processes

- On-time delivery for OEM or aftermarket needs

- Technical guidance for design and installation

Working with a partner like Corrotek ensures you receive components that perform reliably across millions of cycles and challenging environments.

Conclusion: Replace Before It’s Too Late

Ignoring engine mounts replacement signs or delaying suspension bushings replacement can lead to cascading failures damaged chassis, misaligned engines, or unsafe handling.

With India’s automotive landscape evolving under initiatives by ACMA and FICCI, investing in quality rubber components is no longer optional it’s essential for long-term reliability and safety.

If your vehicle or machinery shows signs of vibration, noise, or instability, get it inspected and connect with Corrotek today. Our experts can help you identify, source, and install the right replacement mounts and bushings engineered for performance and built to last.