Choosing the Right Material for Vibration Control in Vehicles and Machinery

In any vehicle or industrial setup, vibration control is a silent yet vital performance parameter. Excessive vibration not only causes discomfort and noise but also accelerates wear, loosens fasteners, and damages precision assemblies. Selecting the right material for vibration damping components such as engine mounts for vibration control, rubber bushings for vibration isolation, and anti vibration pads and cushions is therefore a core engineering decision that directly impacts safety, reliability, and longevity.

In this article, we’ll explore how materials behave under dynamic loads, why selection matters, and what factors make one compound superior to another in vibration control systems.

Why Vibration Control Matters

Every mechanical system—from car engines to CNC machines—produces vibration. If left unchecked, vibration travels through frames, joints, and sensitive assemblies, creating issues such as:

- Structural fatigue and cracking

- Noise and discomfort (NVH issues)

- Reduced machine accuracy or alignment drift

- Shortened component life

In vehicles, excessive vibration from the engine or road can lead to passenger discomfort and loss of control. In industrial systems, it can reduce output quality or damage instruments. Hence, high-quality vibration control components are not optional—they are critical for performance and safety.

According to ACMA (Automotive Component Manufacturers Association), India’s auto-component market exceeded ₹4.2 lakh crore (USD 56.5 billion) in FY 2022, and demand for advanced rubber vibration isolation systems is accelerating, particularly among OEMs focusing on safety, noise reduction, and driver comfort.

Material Science Behind Vibration Isolation

Rubber-based components are widely used for vibration damping because of their unique viscoelastic behavior they absorb kinetic energy and dissipate it as heat. However, not all rubber materials behave the same. The choice of elastomer affects how well a part isolates or transmits vibration.

Common Materials Used

| Material | Key Properties | Typical Application |

| Natural Rubber (NR) | Excellent elasticity and damping | Suspension and chassis mounts |

| EPDM (Ethylene Propylene Diene Monomer) | Heat, ozone, and weather resistance | Engine bay mounts, outdoor machinery |

| NBR (Nitrile Rubber) | Oil and fuel resistance | Engine mounts and seals |

| Neoprene | Balanced oil, ozone, and vibration resistance | Marine and industrial machinery |

| Silicone Rubber | Wide temperature stability | Precision instruments |

| Polyurethane (PU) | High stiffness and durability | Heavy-load mounts and industrial machines |

Selecting between these depends on vibration frequency, operating temperature, load, and exposure to oils or chemicals.

Understanding Engine Mounts for Vibration Control

An engine is a major source of vibration, torque, and noise. Engine mounts for vibration control serve as both load-bearing and isolating components between the engine and chassis.

Functions of Engine Mounts:

- Support engine weight

- Isolate vibration and prevent it from reaching the cabin

- Control engine movement during acceleration or braking

- Maintain alignment of drivetrain components

High-quality mounts combine metal inserts with rubber or composite elastomers that can absorb energy without permanent deformation.

According to McKinsey’s Automotive 2030 Report, NVH (Noise, Vibration, Harshness) performance is among the top five engineering differentiators influencing vehicle brand perception and repeat sales. Hence, OEMs increasingly partner with specialized suppliers for custom mount designs optimized for vibration frequency and amplitude.

Rubber Bushings for Vibration Isolation

Rubber bushings for vibration isolation are used in suspension arms, linkages, machinery joints, and motor assemblies. They act as flexible joints that allow movement while damping transmitted vibration.

Why Material Choice Matters

Bushings must resist compression set, tearing, and creep under continuous stress. If the rubber compound is too soft, the bushing collapses under load; if too stiff, it transmits vibration rather than isolating it. The ideal formulation ensures both resilience and damping balance.

As per BCG’s “Revving Up Exports” report, global OEMs are increasingly sourcing engineered rubber systems from India, especially from clusters like Manesar and Pune, where suppliers such as Corrotek have advanced compounding capabilities and testing infrastructure.

Anti Vibration Pads and Cushions in Industrial Machinery

In manufacturing environments, anti vibration pads and cushions prevent floor vibration, reduce machinery noise, and protect delicate sensors.

Typical Uses:

- Under compressors, generators, and HVAC systems

- CNC and milling machines

- Industrial presses and blowers

These pads combine elastomers, metal inserts, and even layered composites for broad-spectrum vibration attenuation.

According to EY India’s Manufacturing Competitiveness Report, industrial automation is expanding by 12% CAGR, driving higher demand for advanced vibration control materials across sectors like packaging, printing, and automotive assembly lines.

Performance Factors in Selecting Vibration Control Materials

- Dynamic Stiffness – Determines isolation frequency range

- Damping Coefficient – Measures energy absorption

- Environmental Resistance – Resistance to heat, oil, ozone, and UV

- Aging and Fatigue Life – Durability over repetitive cycles

- Load Distribution – Ability to handle static and dynamic loads evenly

Materials like EPDM or NBR are ideal for automotive environments, while neoprene and polyurethane are preferred in industrial machinery for heavier loads and oil exposure.

A 2024 study by FICCI and ACMA emphasized that integrating material R&D in automotive component manufacturing can reduce lifecycle costs by up to 20% a clear case for investing in advanced elastomer technology.

India’s Competitive Edge in Rubber Component Manufacturing

With its skilled engineering base, raw material access, and robust Tier-1 ecosystem, India is rapidly emerging as a preferred sourcing hub for rubber vibration control components.

The Financial Express reported that India’s auto-component exports are expected to touch USD 35 billion by 2028, supported by the government’s PLI scheme and quality-driven manufacturing.

Firms located in Manesar, Gurgaon like Corrotek are at the center of this transformation, serving both automotive and industrial customers across India and overseas.

How Corrotek Ensures Precision and Reliability

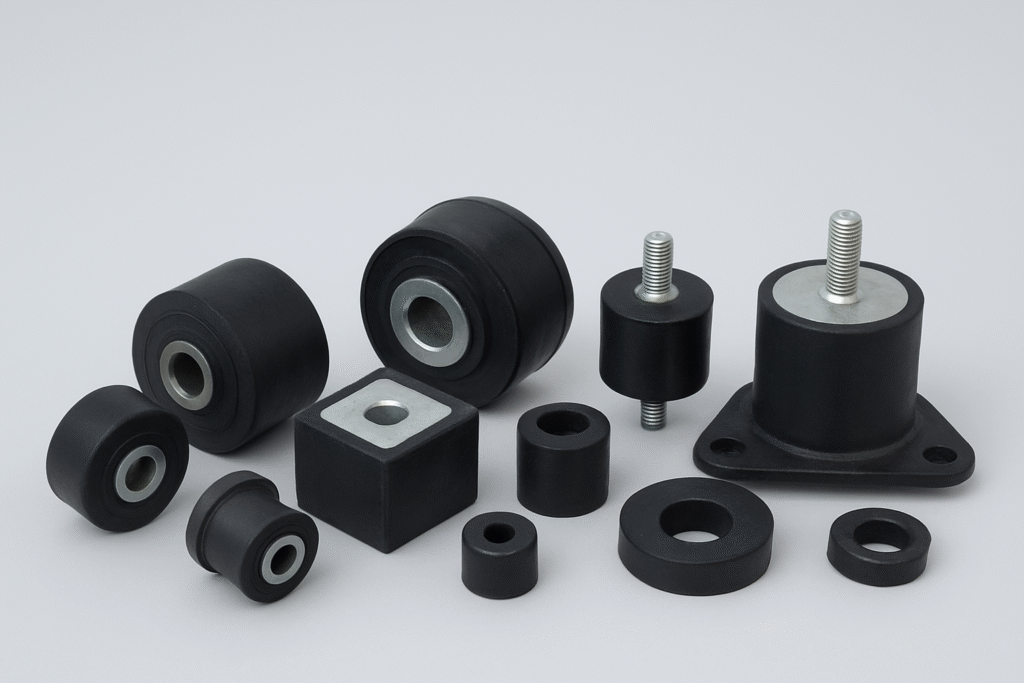

Corrotek is a Manesar-based manufacturer specializing in precision rubber-metal bonded components and vibration-control systems. With in-house design, tooling, and testing capabilities, the company provides tailored solutions in:

- Engine mounts for vibration control

- Rubber bushings for vibration isolation

- Anti vibration pads and cushions

Corrotek’s Advantages

- Advanced rubber compounding and testing lab

- ISO 9001 and IATF 16949 aligned processes

- Rapid prototyping for OEMs and Tier-1s

- Strict dimensional and performance validation

- Custom formulations for specific load and frequency profiles

With every product, Corrotek focuses on material integrity, fatigue resistance, and precision bonding to ensure long-term performance in critical applications.

Key Takeaways

- The right material selection is the foundation of vibration control.

- Natural rubber, NBR, EPDM, and PU each serve specific applications based on load and environment.

- High-quality engine mounts, bushings, and pads enhance comfort, accuracy, and durability.

- Partnering with an experienced manufacturer like Corrotek ensures optimized design, cost efficiency, and safety.

Vibration control is as much about material science as it is about engineering design. Choosing the right elastomer compound can determine whether a system runs smoothly for years or fails prematurely under stress.

As India’s industrial and automotive sectors continue to evolve under initiatives from ACMA, FICCI, and Make in India, investing in premium vibration isolation components is not just good engineering it’s smart business.

If you’re looking for advanced engine mounts for vibration control, rubber bushings for vibration isolation, or anti vibration pads and cushions, connect with the experts at Corrotek today. Our team can help you select the ideal material and design to achieve maximum stability, safety, and performance in your machinery or vehicles.